Exactly How an Optical Fibre Diameter Analyser Enhances Top Quality Control in Fibre Manufacturing

The assimilation of an Optical Fibre Diameter Analyser into Fibre production procedures represents a significant innovation in quality assurance methodologies. By using real-time, accurate dimensions of Fibre sizes, this technology resolves the vital need for uniformity in production requirements. With its capability to promptly recognize inconsistencies and timely restorative procedures, the analyser not just boosts product dependability but likewise adds to general operational effectiveness. As industries progressively prioritize quality and conformity, comprehending the complete impact of such developments ends up being necessary. What effects could this have for the future of Fibre production?

Significance of Fibre Diameter Dimension

Exact measurement of Fibre Diameter is critical in the area of optical Fibre innovation, as it directly influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capacity, depletion, and general transmission effectiveness. Accuracy in measuring Fibre Diameter makes certain that the optical residential properties are preserved within defined tolerances, which is important for ideal signal honesty.

Variations in Fibre Diameter can result in raised losses because of spreading and modal diffusion, impacting the top quality of data transmission. In high-speed communication systems, such inconsistencies can lead to considerable destruction of signal quality, causing data errors and minimized performance. Additionally, regular Fibre Diameter is essential for compatibility with connectors and splicing modern technologies, which are essential components of Fibre optic networks.

Quality control procedures in Fibre manufacturing greatly rely on exact Diameter measurements to make sure compliance with market requirements. By executing durable measurement strategies, makers can enhance item dependability, minimize waste, and boost general system performance. Thus, the importance of Fibre Diameter measurement can not be overstated, as it offers as a keystone in the improvement of optical Fibre technology and its applications in contemporary communication networks.

Just How the Analyser Functions

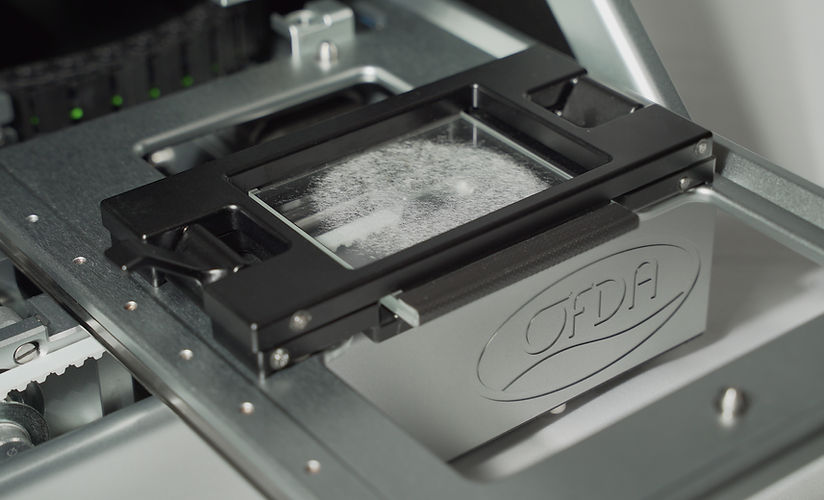

The effective dimension of Fibre Diameter depends on sophisticated logical techniques that make sure precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser technology and progressed photo processing algorithms to properly assess the Diameter of fibres as they are created

Originally, a laser beam is routed at the moving Fibre, producing a cross-sectional shadow. The analyser captures this darkness using high-resolution electronic cameras positioned strategically along the production line. The captured photos are then processed in real-time to figure out the Fibre's Diameter with extraordinary accuracy.

The system utilizes advanced algorithms that account for different elements, consisting of variants in light intensity and environmental problems, to improve measurement dependability. It can discover minute modifications in Diameter, such as changes that may occur during the production procedure.

Moreover, the analyser can managing numerous fibres simultaneously, enhancing throughput without endangering accuracy. By providing instantaneous comments on the Diameter, the Optical Fibre Diameter Analyser plays a critical function in keeping strict top quality control requirements, making sure that the end product meets industry specifications and customer demands.

Advantages of Real-Time Monitoring

While standard approaches of monitoring Fibre Diameter usually entail taxing post-production checks, real-time surveillance considerably enhances the efficiency and quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive technique permits suppliers to recognize deviations in Fibre Diameter as they take place, as opposed to waiting till manufacturing is full to examine high quality

By continuously measuring the Diameter during manufacturing, producers can guarantee that the fibres meet stringent requirements, causing lowered irregularity and boosted uniformity. Real-time surveillance likewise allows instant restorative activities to be taken, minimizing waste and stopping malfunctioning fibers from going into the supply chain.

Furthermore, this innovation helps with enhanced information collection and evaluation, supplying insights into manufacturing fads and prospective areas for renovation. Such data-driven decision-making equips producers to optimize processes and preserve high standards of quality assurance.

Furthermore, real-time tracking promotes a culture of constant improvement within the production atmosphere. Staff members are extra engaged when they can see the impact of their job in real-time, leading to increased liability and a dedication to excellence. Overall, the application of real-time surveillance systems in optical Fibre production equates to premium product high quality and enhanced consumer fulfillment.

Effect On Production Effectiveness

Carrying out optical Fibre Diameter analysers dramatically improves manufacturing effectiveness by streamlining the manufacturing process. These gadgets promote continual monitoring of Fibre Diameter, enabling manufacturers to discover variances in real-time. By identifying disparities quickly, manufacturing lines can be readjusted promptly, decreasing read review downtime and lowering the probability of producing faulty products.

Moreover, the integration of these analysers right into the manufacturing operations allows better resource appropriation. With accurate Diameter dimensions, operators can optimize material usage, ensuring that resources are not thrown away on problematic fibres. This precision also contributes to additional hints much less rework and junk, inevitably decreasing manufacturing costs.

The automation supplied by optical Fibre Diameter analysers lowers reliance on hand-operated assessments, which are prone and commonly lengthy to human error. Because of this, workers can concentrate on even more strategic jobs, boosting general productivity.

Furthermore, the data produced from these analysers can educate procedure renovations and assist in much better decision-making. By examining trends in Fibre Diameter variants, suppliers can carry out aggressive procedures to enhance manufacturing methods and preserve regular high quality. In summary, optical Fibre Diameter analysers play an essential duty in improving production efficiency, bring about greater top quality outcome and increased earnings.

Instance Studies and Success Stories

Across different sectors, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing processes. One famous instance is a leading telecoms company that faced difficulties with irregular Fibre diameters, bring about enhanced rejection prices. By incorporating an optical Fibre Diameter analyser, the company attained real-time tracking of Fibre measurements, resulting in a 30% reduction in defects and substantial expense financial savings.

In addition, a research organization concentrating on advanced products utilized optical Fibre Diameter analysers to fine-tune their experimental processes. The analyser's ability to supply comprehensive insights right into Fibre consistency enabled the growth of cutting-edge materials with enhanced efficiency characteristics.

These success stories underscore the crucial duty of optical Fibre Diameter analysers in enhancing quality assurance, boosting production efficiency, and driving technology throughout diverse industries.

Final Thought

In conclusion, the Optical Fibre Diameter Analyser plays a critical role in enhancing quality control within Fibre manufacturing. As shown via different situation research studies, the analyser basics proves important for attaining exceptional product quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers permitted for stringent quality control, making certain that the produced fibres satisfied exacting sector criteria.In verdict, the Optical Fibre Diameter Analyser plays a crucial duty in enhancing quality control within Fibre production.

Luke Perry Then & Now!

Luke Perry Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!